The optimisation of machines, increasing the capacity of a production line or determining the layout of a completely new factory. That is what the engineers of our Production Lines & Machinery department are working on every day. For example, do you have a challenge with existing production lines in the area of capacity, buffer distances, walking routes or food safety? Or do you want a strength calculation of machines (FEM) or air and fluid flows (CFD)? Thanks to years of experience and expertise, our engineers will always find a good technical solution for your problem, no matter how complex it is.

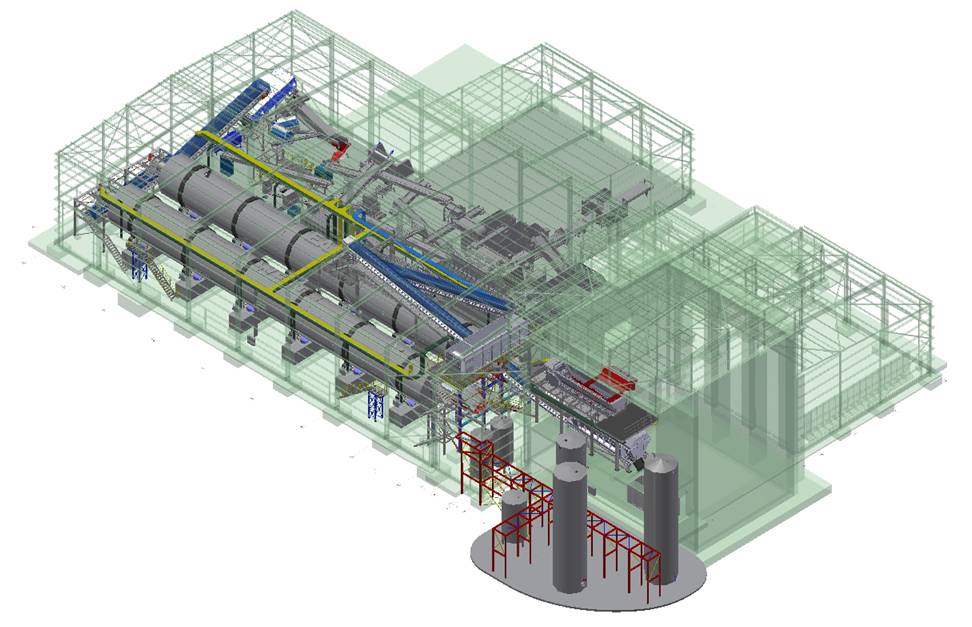

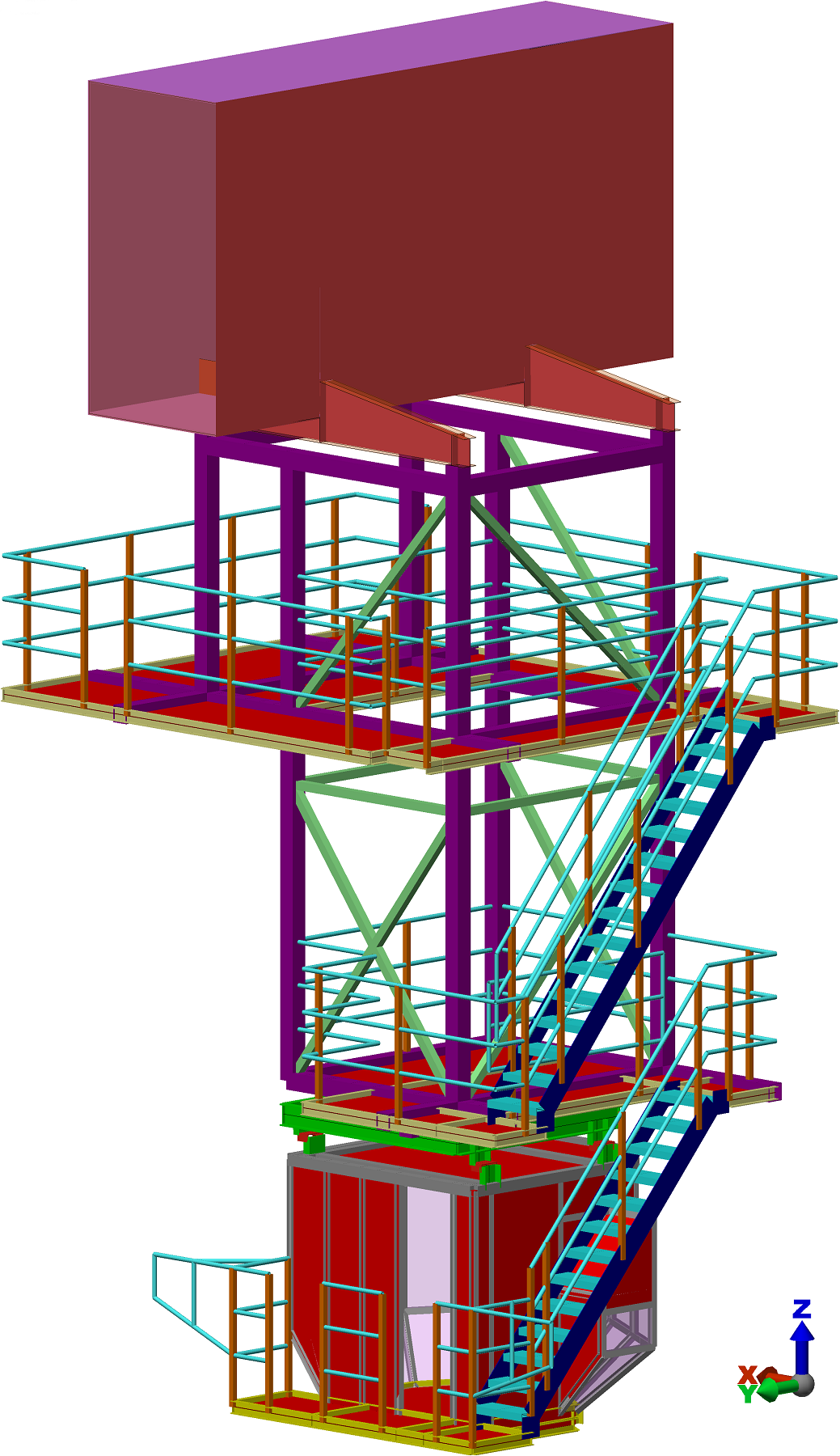

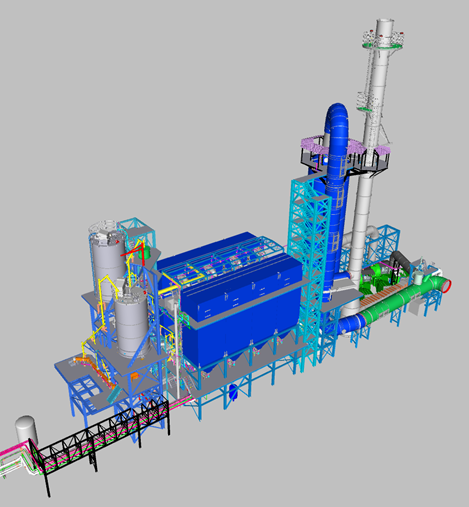

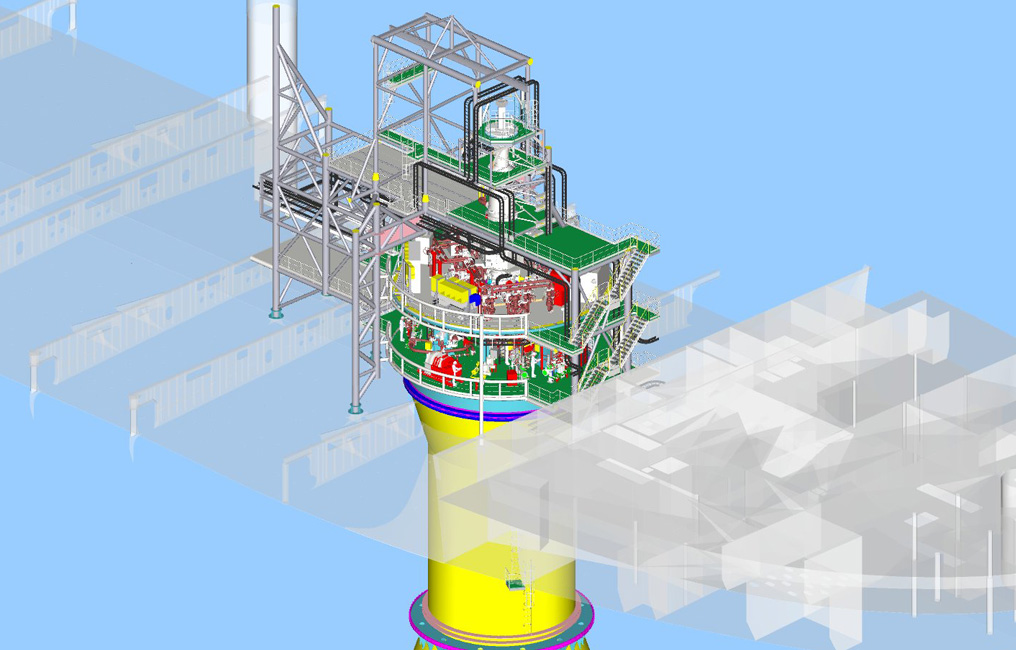

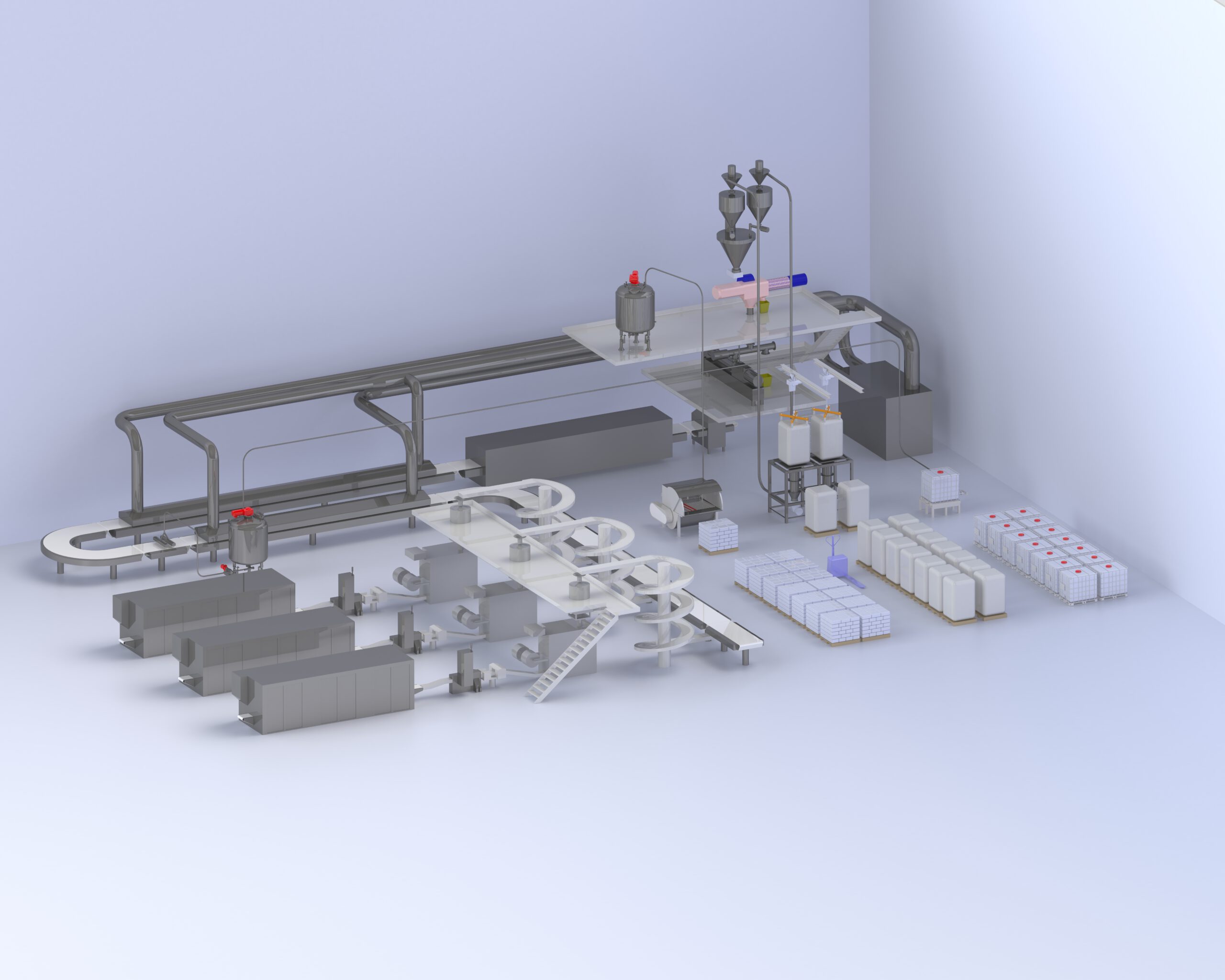

Optimal production thanks to 3D models

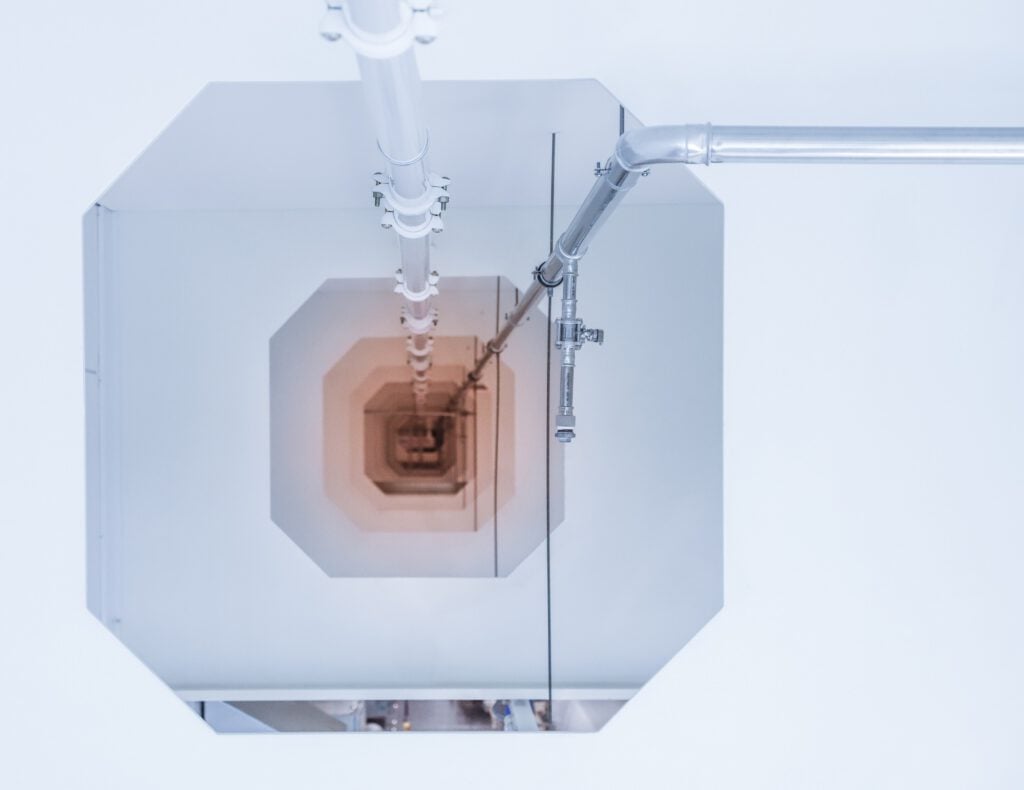

Are you developing new production lines or opening a completely new factory? Then we will make a 3D model of the layout. We position machines, conveyor belts, pipelines and platforms in such a way as to create an easily accessible product flow for goods and personnel. We take into account your specific wishes, such as capacity targets or walking routes. Even when it concerns an existing production line, our specialists make a 3D scan of the current equipment. They develop an improved layout to improve accessibility and increase capacity within the same dimensions.

The phases we go through in a project

Our engineers are involved in your project from the very first initiative, enjoy short lines of communication and do what they promise. The phases we go through in a new production line are:

- We take note of your wishes and request P&IDs

- Optional: we plan, make and process a 3D scan

- We make a sketch design for discussion

- You receive the concept design or global layout, which we discuss with all stakeholders until agreement is reached

- We draw up a detailed design, compare it in NavisWorks with other models (for example, from colleagues in Architecture & Building or Civil Engineering) and make adjustments where necessary

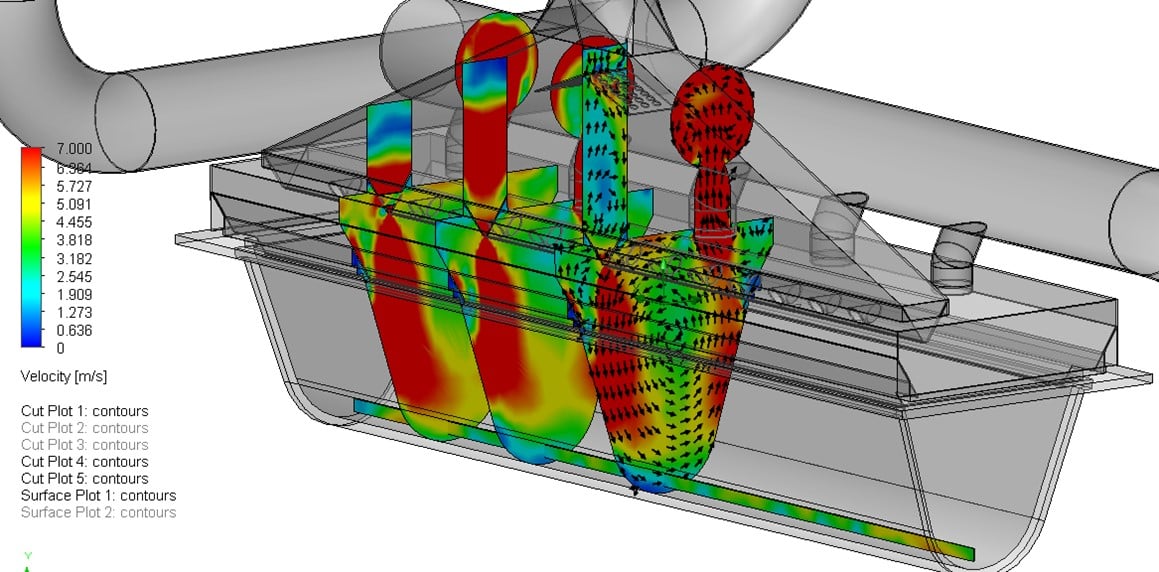

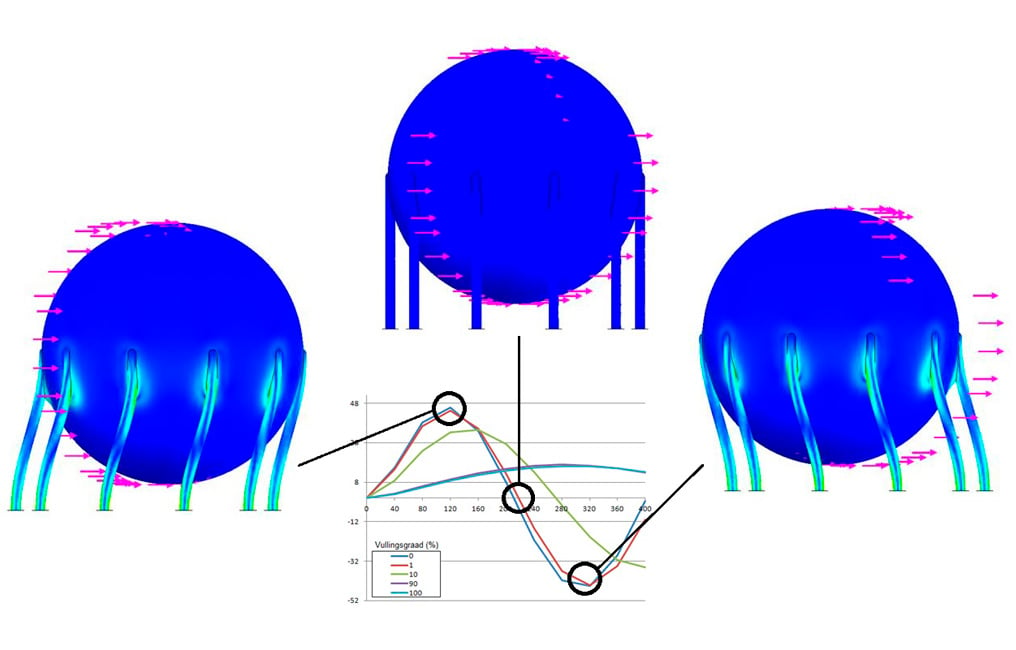

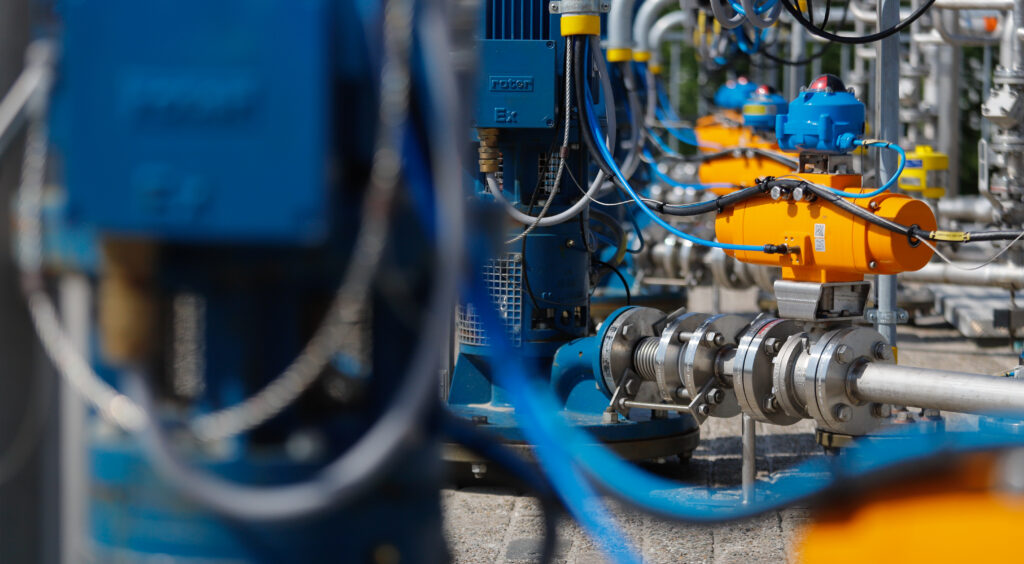

Machines that do what they have to do

Do you want to calculate the lifespan of a shaft in a mixer, or check whether installations or pressure vessels are explosion-proof? Or do you want to know the suction power of a hood? These are the daily questions of our engineers in the field of Mechanical Engineering. They perform force calculations on machines (FEM), analyse air and fluid flows (CFD) and check machines in the field of machine guidelines and CE. In short, they examine for you as a client whether machines function properly, are safe, remain intact and comply with standards.