Steel producers generally use tipping skips, large containers that keep the chunks of steel left over from the casting process. The skip is regularly tilted on its side to dispose of the contents. This does cause a lot of dust to the thrown in the room. To prevent this, a special extraction unit was designed that can remove the residual dust, so that the amount of dust in the work area is significantly reduced.

Project: design for tipping skip

Various disciplines are needed to reach the best solution: designing the extractor unit, making modifications to the tilting skip, installing new ducts and connecting them to the existing system, selecting fans and valves, and making calculations of the building’s steel structure.

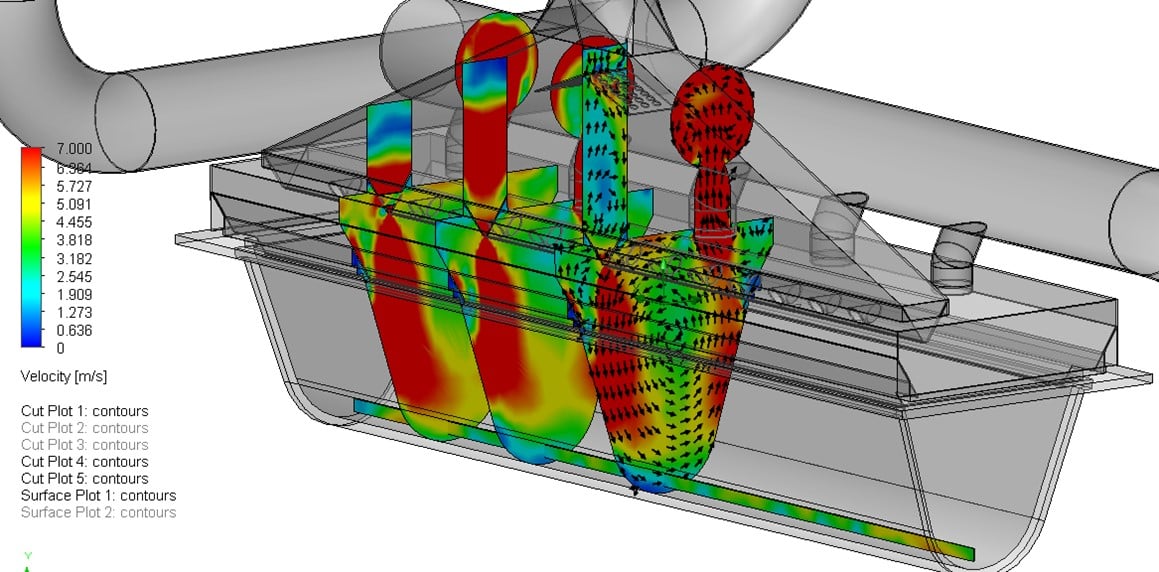

This article only looks at the work that was carried out with CFD (Computational Fluid Dynamics). A key element, for example, is evenly distributing the air velocity across the tilting skip. And there also needs to be sufficient air velocity at the bottom of the tilting skip, while no air should be allowed to flow out through the gaps between the tilting skip and the extraction unit. CFD was applied to calculate the pressure losses in the ducts for the selection of the fan, valves, etc., as well as for determining air velocities in the ducts to choose the duct diameter, and for determining the temperature of the exhaust air.

Vicoma’s role: CFD calculations

Vicoma performed CFD calculations for each of the above aspects. A summary: Een kort overzicht:

Even distribution of air velocity

The CFD calculations optimised the blower nozzle to distribute the air velocity as evenly as possible over the entire outlet opening. This has already been partly achieved by the resistance of the narrow outlet opening. In addition, baffles have been placed in the nozzle to guide the air out.

Sufficient air velocity at the bottom of the tilting skip

Using the calculations from the CFD, the position of the blower nozzle and the extraction pipe could be optimised to ensure maximum air velocity at the bottom of the tilting skip. The influence of reducing the size of the outlet opening at the blower nozzle for optimum airflow was also considered.

No air flowing out through the gaps

It is important to prevent air – and therefore dust – from flowing out through the cracks of the tilting skip. The calculations showed that it is practically impossible to stop air from leaking out with the limited difference in flow rates. It was therefore decided to physically seal the gaps with a hinged construction.

Pressure losses in the duct

The pressure losses in the duct were determined with Fluidflow, but can also be deduced from the CFD calculation. The advantage of the CFD calculation is that it also specified the pressure losses of the nozzle opening and tilting skip. This gave a comprehensive view of the entire system.

Determining air velocity in the duct

The extracted air contains debris and dust. To limit wear in the ducts, the maximum air speed in the return duct was limited to 15 m/s. The optimum pipe diameters and radii for the bends were selected based on the velocities according to the CFD calculation.

Determining return air temperature

The temperature inside the tilting skip is still around 750 °C during extraction. Any cold outside air that is blown in therefore heats up. The CFD calculation was used to determine what the temperature of the exhaust air will be.

Result: optimal design

The CFD calculations helped Vicoma to devise the optimal design to extract dust and air from tipping skips for a very satisfied customer.