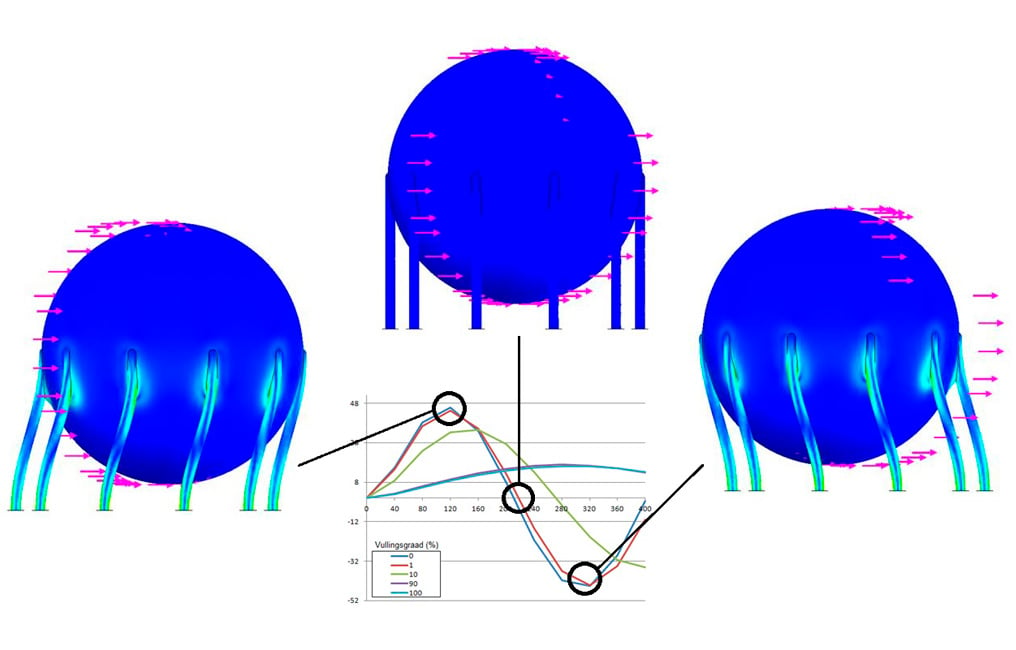

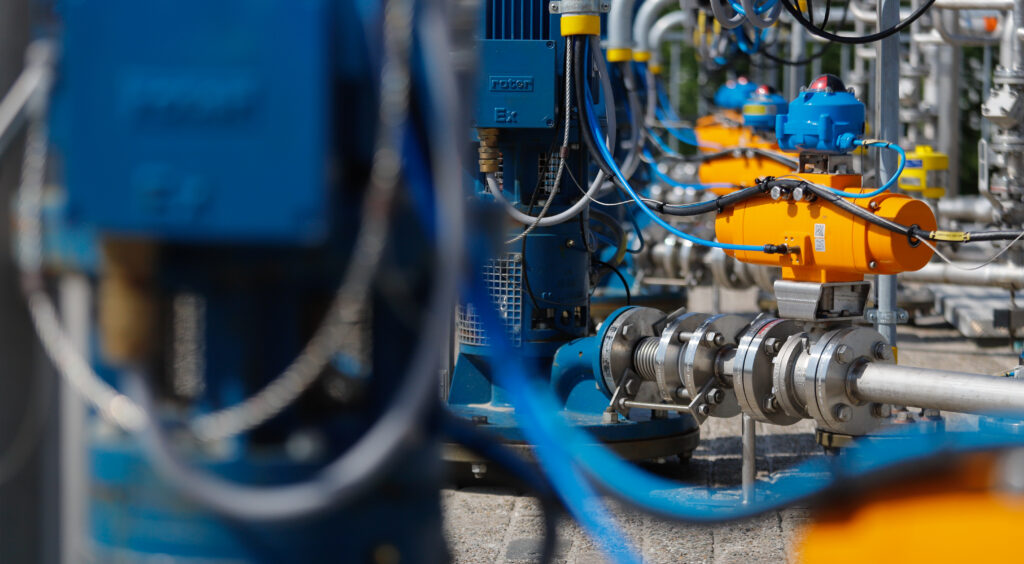

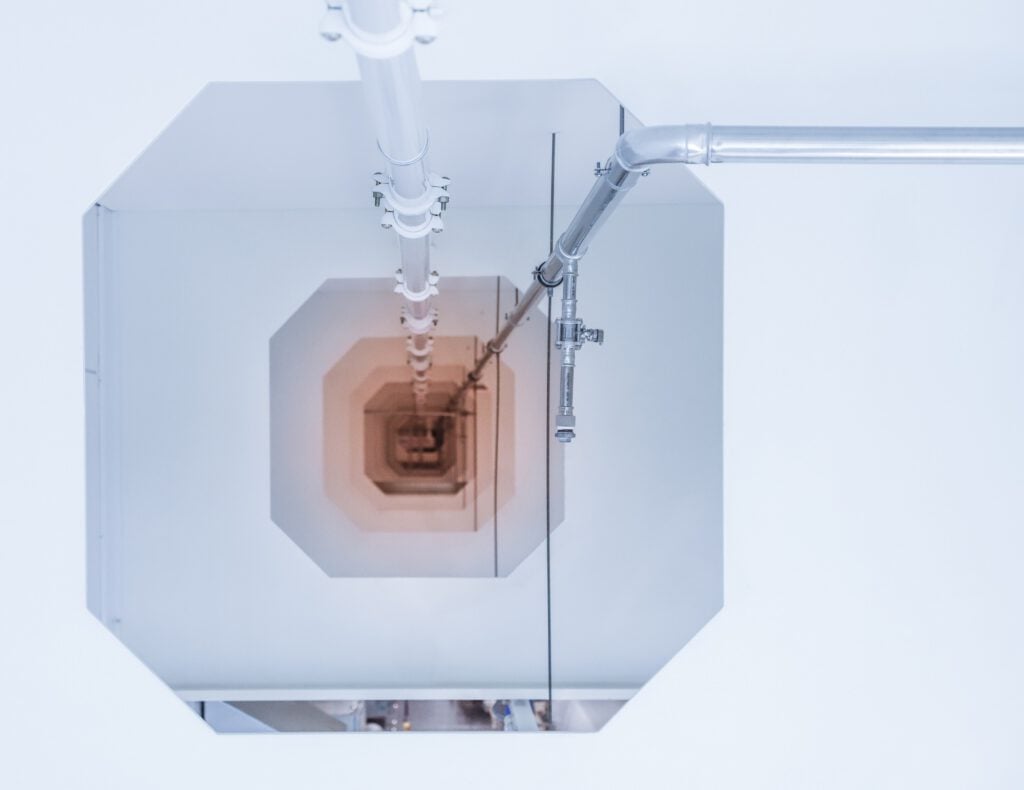

Do you have a challenge in the field of environment and sustainability, capacity expansion or safety? The engineers in our Piping department work on designs and budgets for new process installations and modifications to existing process installations. Whether it is designing new tank pits or pump manifolds for tank terminals, or replacing equipment for (petro)chemical plants, Vicoma provides piping systems of the highest quality. Thanks to years of experience and expertise within the field, we have a suitable solution for every problem.

Piping department

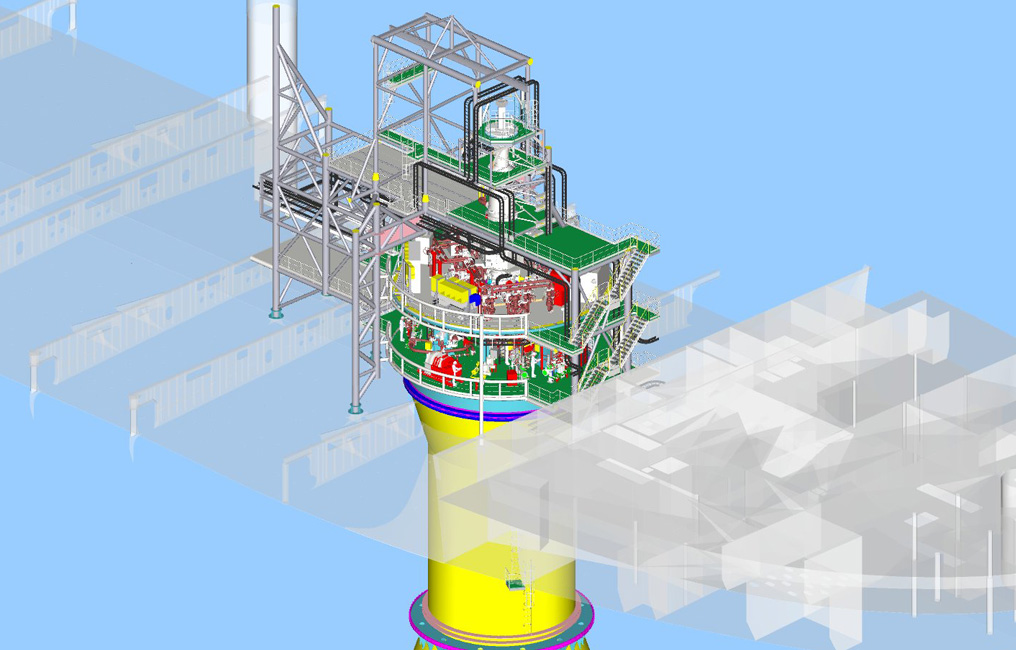

Within Piping you want to design an installation that is as cost effective as possible, easy to operate and maintain. But that is not all; the system must also meet all legal requirements, standards and regulations. At Vicoma we are aware of all these challenges; our Piping department works closely together with specialists from other disciplines to form a spider in a web. This way we include all required physical areas, such as CSA, E&I boxes, cable runs and ducting, in our designs.

Steps within a Piping project

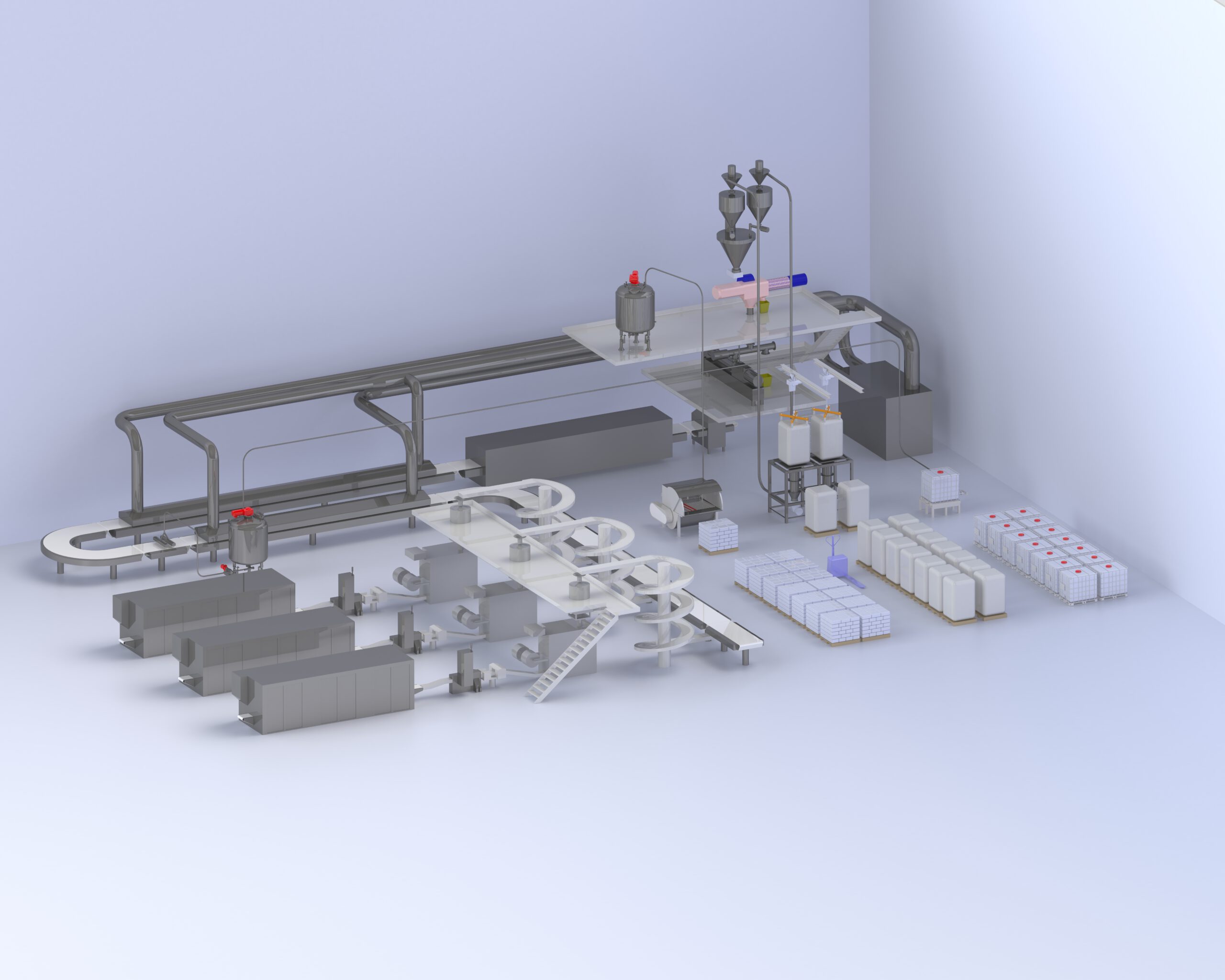

The engineers in our Piping department will fully support you in the design and budgeting of new piping systems or the expansion of existing ones. We take a pragmatic approach, work closely with you as the client and our specialists are quick to respond. During the entire term, we coordinate the work with all the internal departments and external parties involved.

- Roughly speaking, a Piping project consists of the following steps:

- We agree the scope with you and, if you wish, we plan a site visit

- After approval of the proposal, we organise a kick-off with all those involved

- Together with your own employees or our colleagues from Process, we edit the P&IDs for any demolition or new construction work

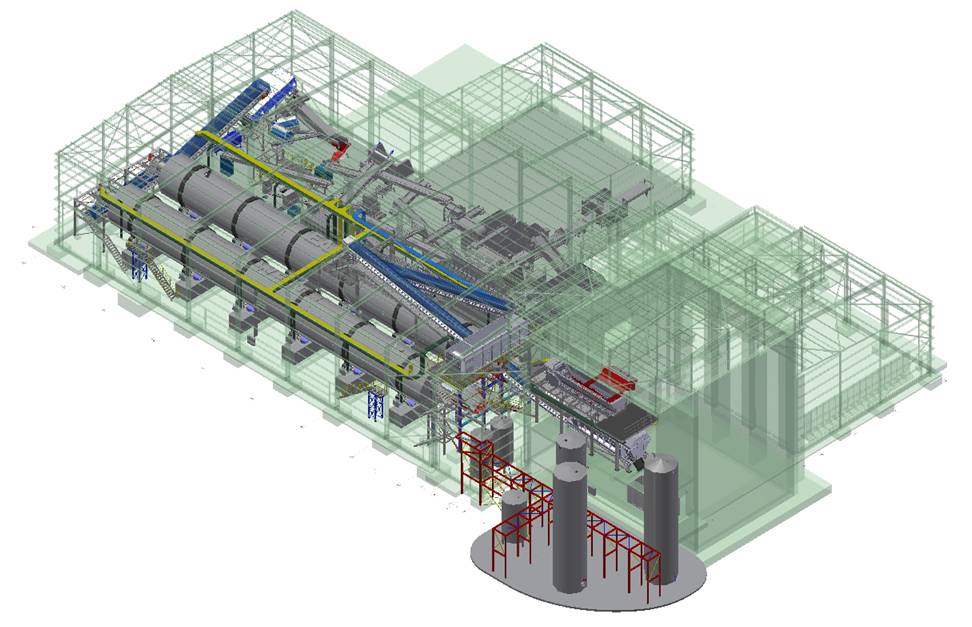

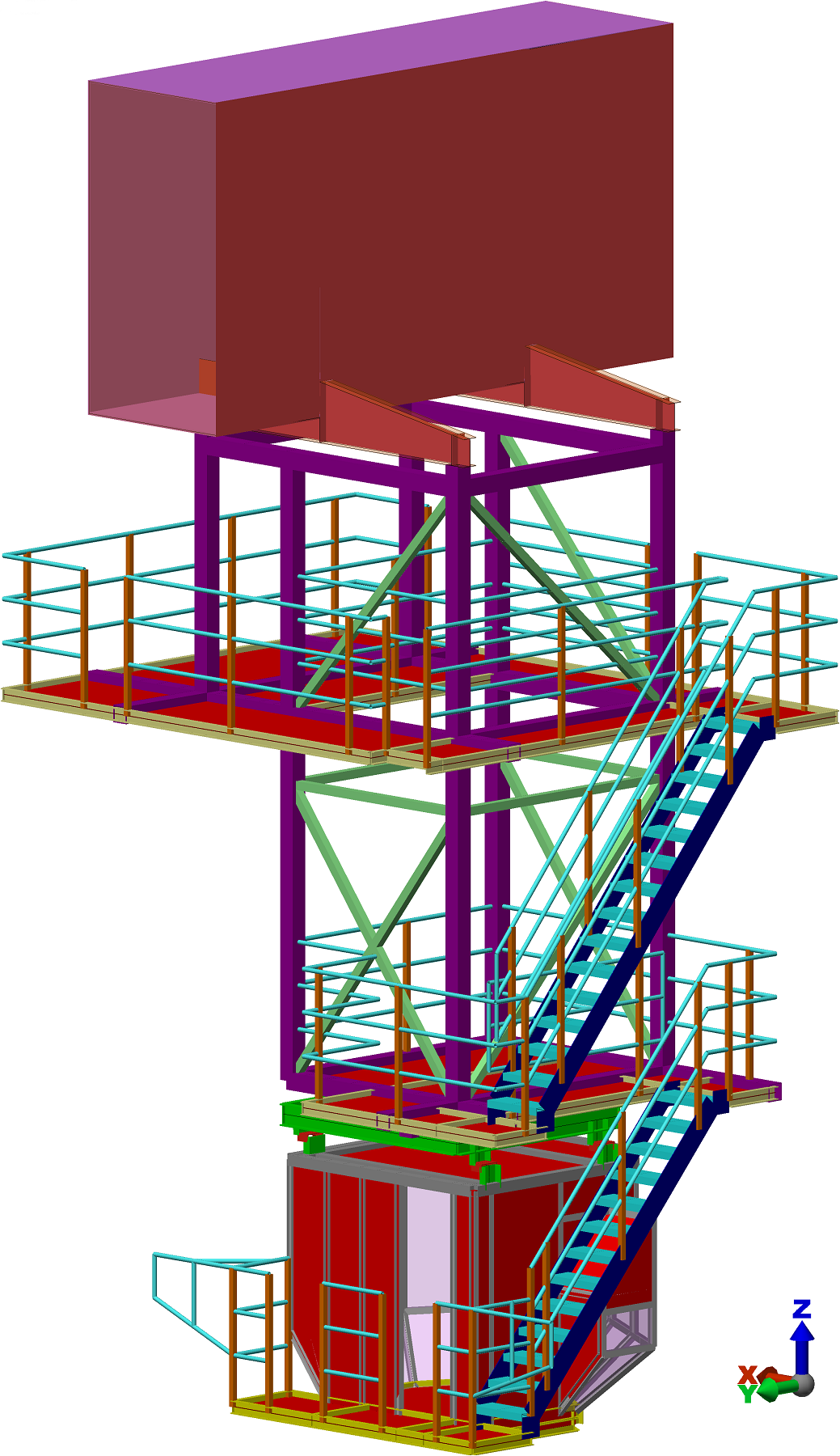

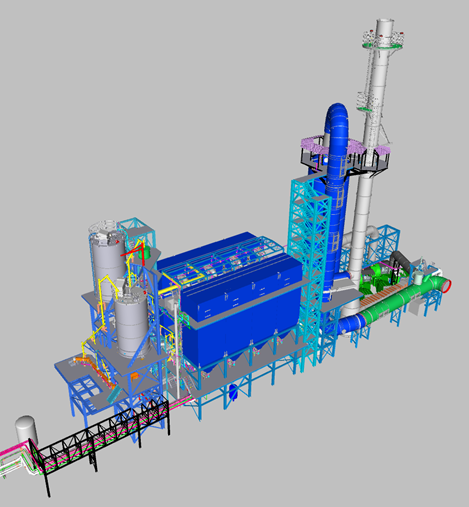

- We include existing situations in the design, manually or via 3D scanning

- We design new installations and, if necessary, describe the demolition of (parts of) the installation

- We come up with a 3D model for the installation for review and put together packages for implementation