The vision of a specialist in technology for innovative urban agriculture is to produce food sustainably and efficiently by reducing water consumption, transport costs and energy costs. In light of the constant innovations and new developments that the company is working on, it asked Vicoma to perform a safety scan to guarantee the safety at all times and in every situation for its staff.

Project: from sowing to harvesting

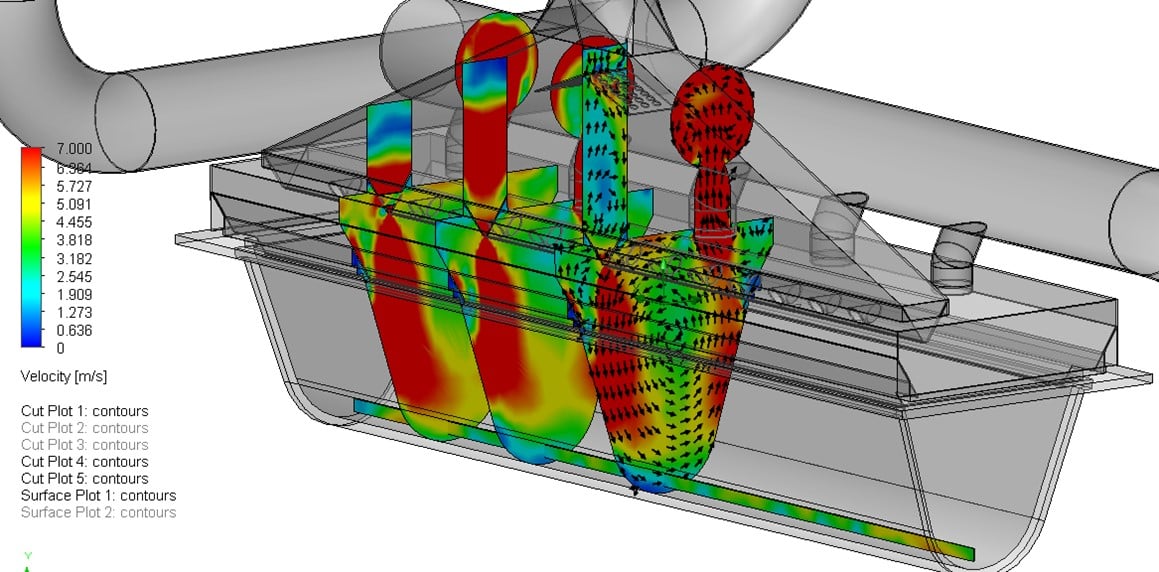

The company consists of several different departments. In the sowing department, machines fill trays with soil in a production line before seeds are also automatically planted. In the department where the growing process takes place, there are a number of conditioned rooms with their own climate control systems and water treatment. The young plants are transferred to a production line in the harvesting department, where they are automatically cut just above ground level. The air treatment units require hot and cold water, glycol and carbon-dioxide, which are produced in the utility room.

Vicoma’s role: conducting safety scan

Vicoma is a company consisting of a multidisciplinary team with extensive experience in different fields of expertise, including civil engineering, machine safety and food safety. The project manager could thus call in the help of colleagues with the the required specialist knowledge, and could easily perform a one-stop-shop safety scan on site that covered all the main facets. Among other things, it checked compliance with the Machinery Directive requirements and standards. It also looked at working conditions, occupational health and safety legislation, and hygiene guidelines. That last point is essential, considering the company’s main area of business is food. The final inspection looked at whether the building complies with the Building Regulations.

Result: fine-tuning based on safety scan

The safety scan showed that the standards of the company were already adequately in place in terms of health and safety, but could still use some fine-tuning. Vicoma gave the company a number of helpful tools that will enable it to further improve safety levels in the future.