Facing challenges in your production process, such as increasing capacity, selecting the right equipment, ensuring food safety or meeting strict safety regulations?

Vicoma provides technical solutions tailored to your operation. Whether you want to improve your production line or upgrade essential equipment, our engineers combine expertise and practical insight to solve even the most complex challenges. With decades of experience, we deliver reliable and future proof solutions that fit your plant and your ambitions.

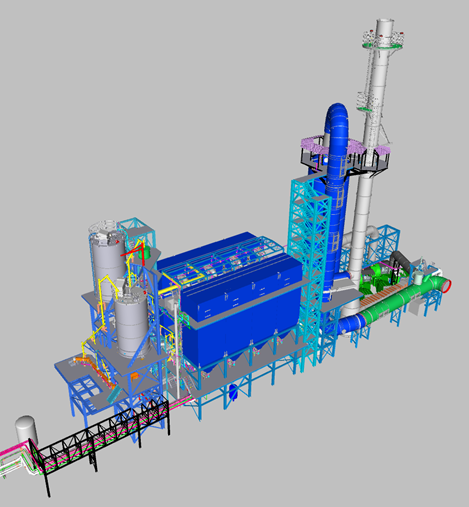

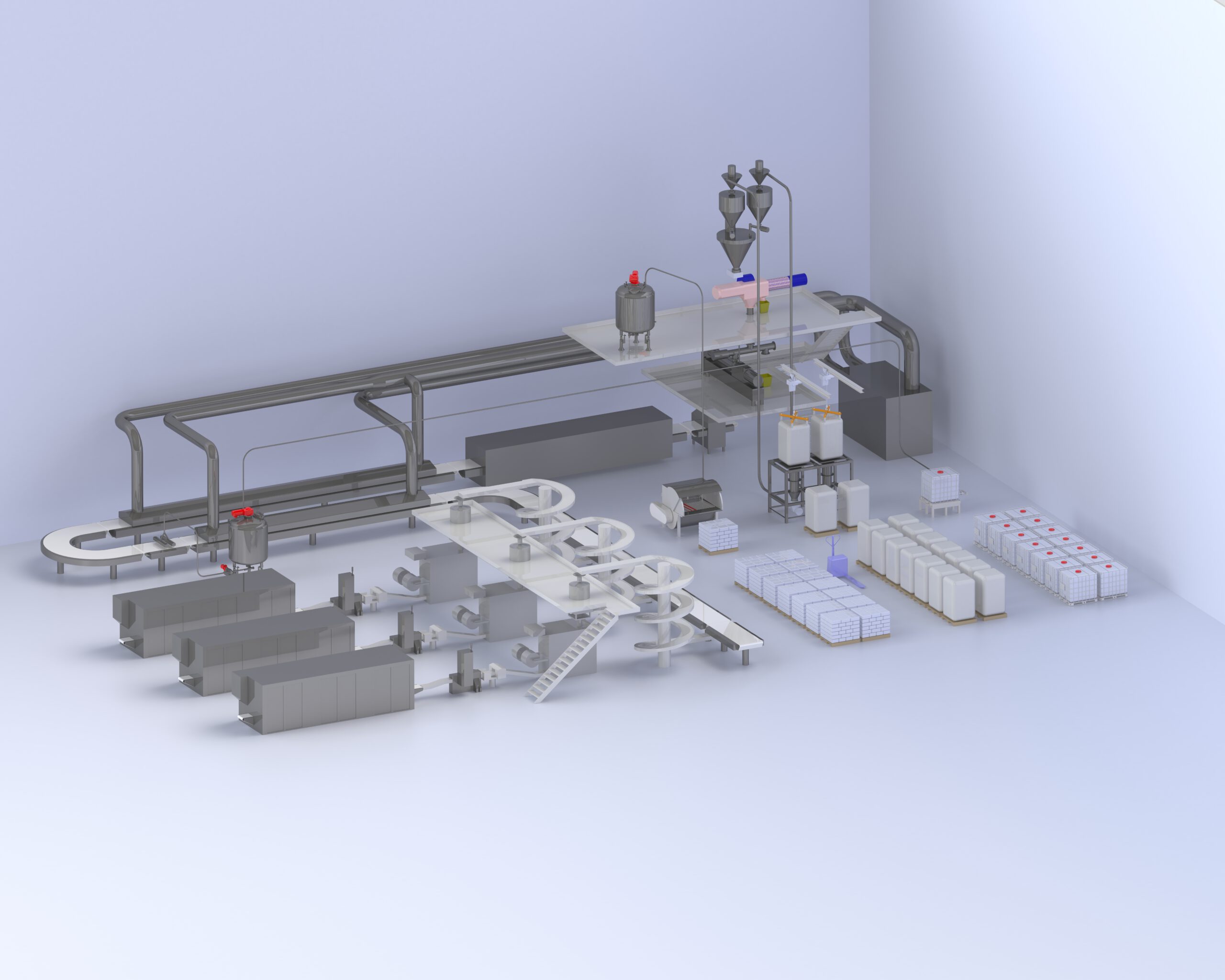

Factory Design

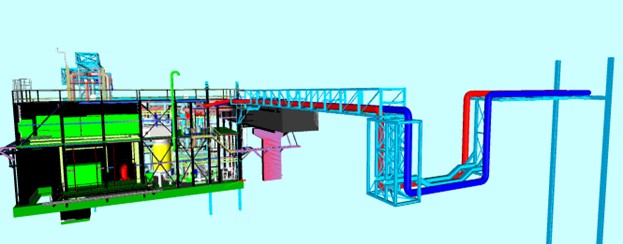

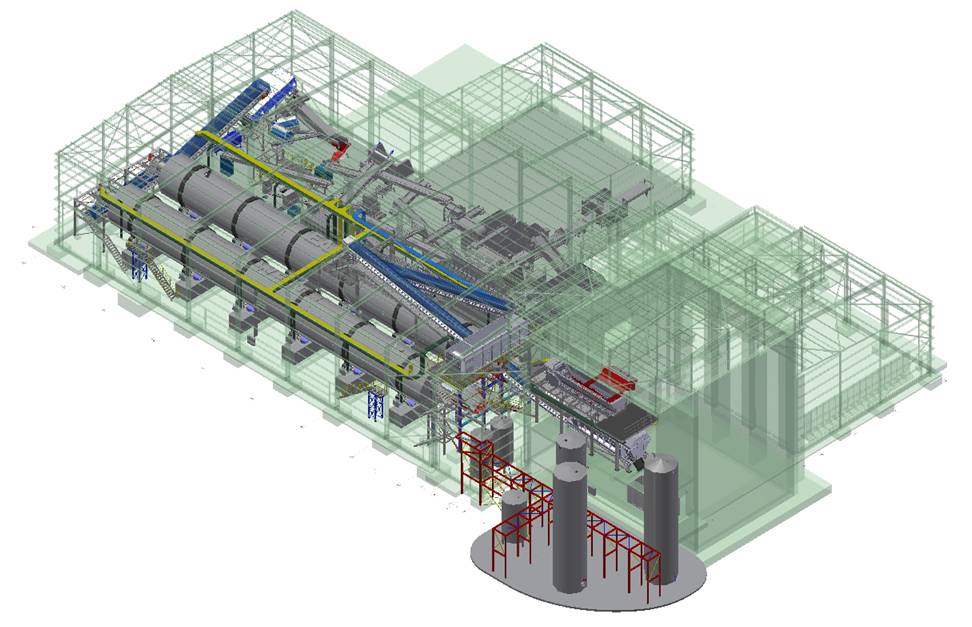

Smart support for plant extensions and production line modifications

Every production process is unique. Our engineers work closely with you to understand your operation and define all requirements at an early stage. By asking the right questions, we prevent issues later in the project and deliver a clear and detailed specification that you can use for supplier quotations. If needed, we assist with the selection of suitable suppliers.

We start by creating a three dimensional concept layout. For existing sites, we perform an accurate three dimensional scan of the current situation. The layout provides clear insight into the future configuration of your plant, identifies clashes at an early stage and reveals opportunities for improvement.

If desired, we can offer a virtual tour, ideal for operator training or investment reviews.

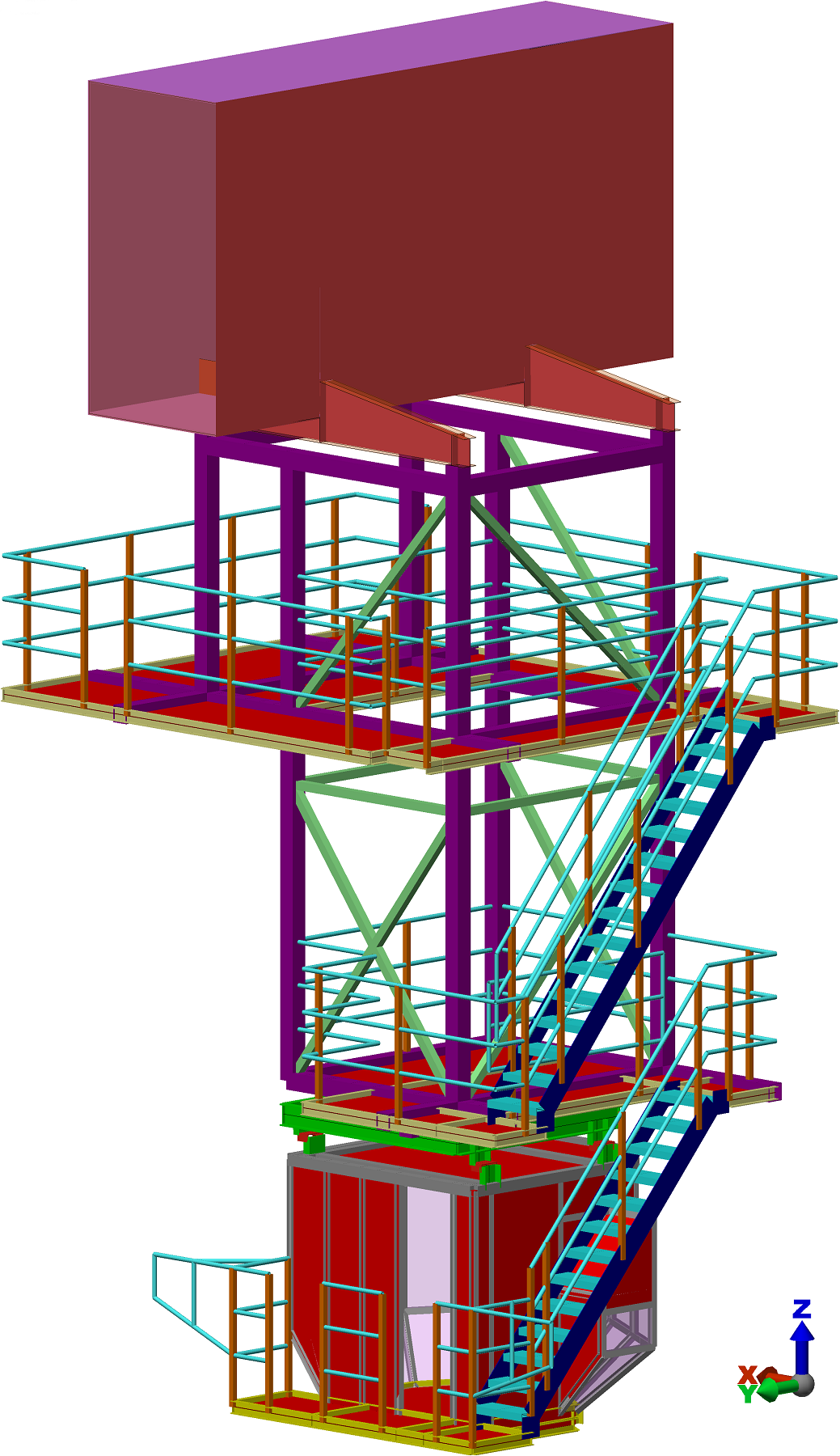

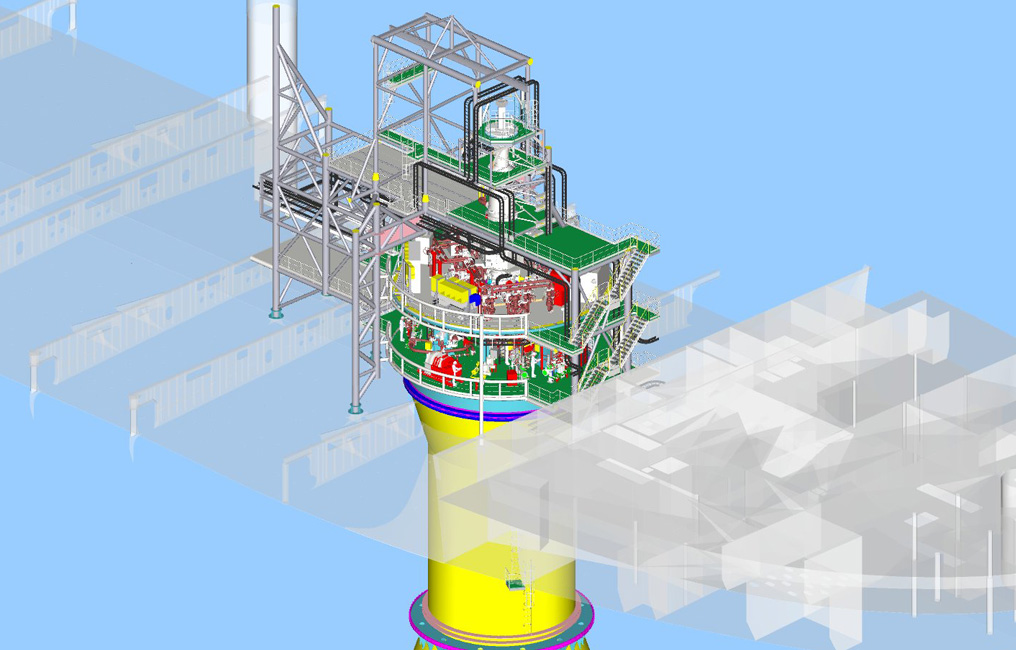

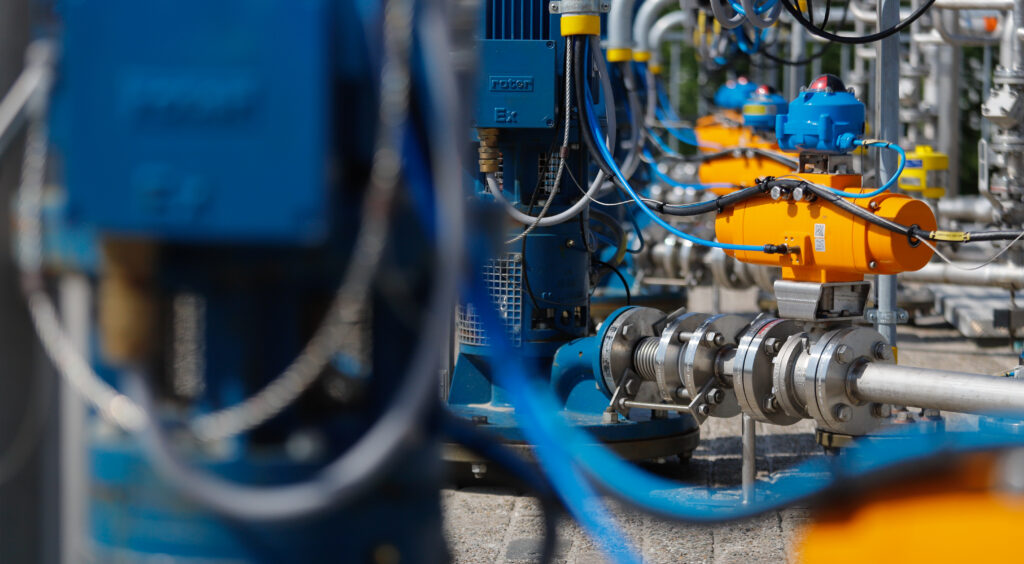

Mechanical Engineering

Smart design and modification solutions for your equipment

We design, modify and optimise equipment such as cranes, conveyors, skids, silos and offshore installations.

From the first concept to execution, we work with a clear plan of approach so you know exactly what to expect. When working with existing installations, we use three dimensional scanning to capture the situation and integrate new components efficiently.

Throughout the process we communicate clearly, work pragmatically and ensure compliance with all applicable standards and regulations. Whether you need concept development, tender support, basic engineering or detail engineering, you can rely on us.

By collaborating across disciplines, we often realise significant operational savings in large investment projects.

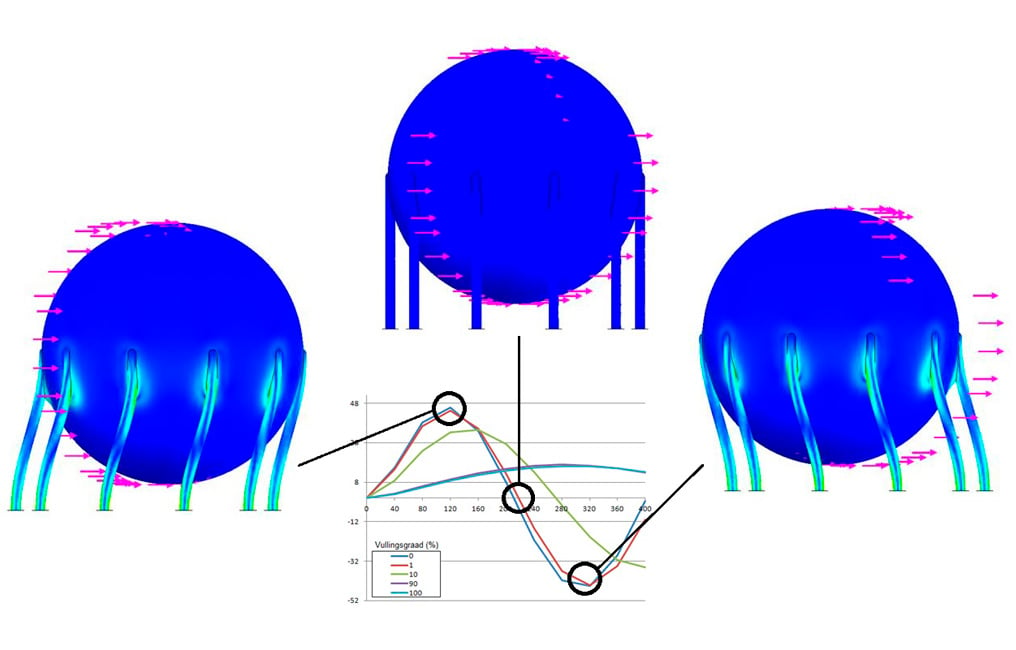

Finite Element Method (FEM)

Strength and stability for your equipment

Our engineers perform FEM analyses to assess the strength, stability and remaining service life of equipment. We analyse complex geometries and various loading conditions to achieve an optimal and safe design.

All results are documented in clear reports that meet the requirements of certification authorities.

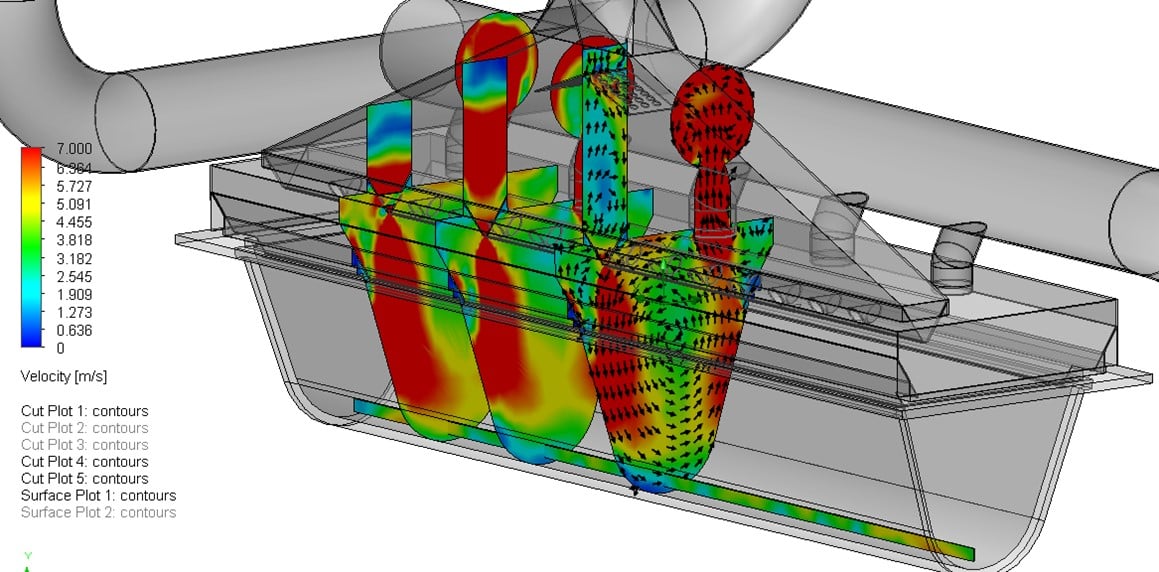

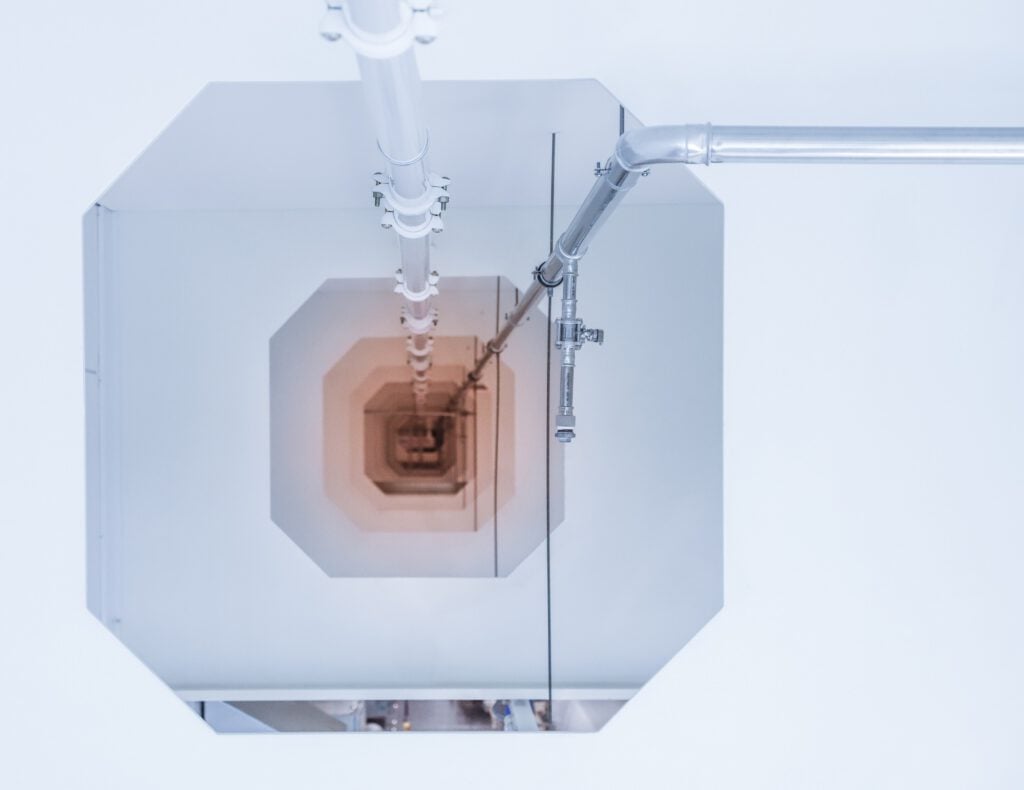

Computational Fluid Dynamics (CFD)

Optimise flow behaviour and temperature distribution

CFD allows us to analyse liquid and gas flows and to visualise temperature patterns. We calculate pressure drops, simulate gas concentration levels and assess airflow distribution within equipment.

These insights help optimise your design and identify bottlenecks before they arise.

Safety Studies (CE Marking)

A safe working environment and full compliance with regulations

Introducing new equipment, modifying existing systems or combining installations requires a strong focus on safety.

Our specialists understand CE marking, occupational health regulations and the full scope of machine safety standards. They guide you through the requirements and can manage the full CE process if needed.

Would you like to learn more about machine safety? Click here for our leaflet.

Ready to discuss your challenge?

Whether you want to improve your production line, upgrade equipment or explore optimisation opportunities, we are ready to help.

Contact us to speak with one of our experts.